Details

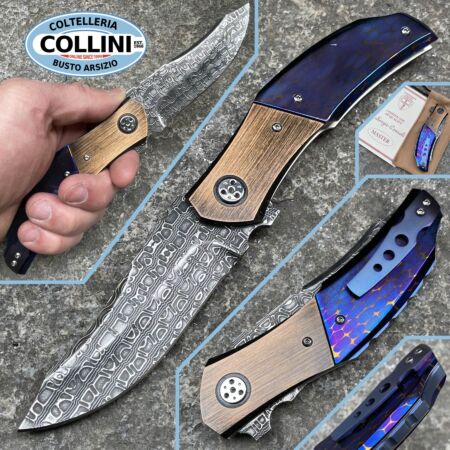

Intended use: Collection

Type of production: Artisan by CIC Master Sergio Consoli

Production Lama: Italy

Blade: In spirograph damascus steel

Blade treatment: -

Handle: bronze bolsters, timascus with titanium spacers

Blade length: 95mm.

Blade thickness: 4mm.

Total length: 225mm.

Weight: 243g.

Closure: Liner Lock

Clip: titanium

Notes: Handmade by Master Sergio Consoli - knife number 454 made in 2018

Acknowledgments

Currently I make a limited number of knives a year and participate in some exhibitions, where among other things I have won my first prizes:

in 2005 at LAME SOTTO I PORTICI in Romano di Lombardia (BG) I was awarded as "best table on display"

always in the same year at the CULTER-EXPO in Novegro (MI) as "best folding knife"

I was also ranked second in the competition organized by the magazine LAME D'AUTORE as the best fixed hunting blade

then in 2007 at "Scarperia" I won the third prize for best folding

but above all again in 2007, to my great satisfaction, I reached the degree of MASTER OF THE ITALIAN KNIVING CORPORATION, a recognition received at the first exam.

Presentation of the craftsman

Creating a knife by hand is what I consider a real art form.

The satisfaction of seeing an object that comes from one's own hands, that takes shape and reaches mechanical, artistic and aesthetic perfection is what pays me back the most for all the hours of work and effort it takes to create a knife completely. by hand.

The passion for "cutting tools" has always been in me since I was a child and grew with me until the almost sudden decision to build my first knife myself, it was a "need", almost an inner necessity that I couldn't put off, my hands and my mind had to start creating, of course, what I had always been passionate about ... the knife!

I started at 40, in 2003, practically self-taught, I had no experience of manual work, but I had been a mechanical designer for many years and this allowed me to perfectly know the technique and all the various stages of mechanical processing.

Currently I am a member, with the rank of Master, which is the highest, of the Italian Knives Guild, an association recognized all over the world for the seriousness and above all quality of execution that all its members must maintain over time.

What I do now is what I consider my art form ..., to create "handcrafted, hunting and collectible knives".

They are knives made entirely by hand, only with an infinite series of files, a small drill for the holes and a sander for the concave grinding of the blades, nothing else!

I mainly make folding knives, which satisfy my desire to build perfect mechanical objects and perfection in the smallest details, even inside where they are not seen, is what distinguishes a knife created by hand, from one made industrially .

The mechanics then must be made in the best possible way, without counting the hours of work, only in this way the final result is guaranteed.

Of course, over the years I have refined my technique and currently I have improved the mechanics even more by inserting a system of ball bearings on the blade rotation, which guarantee an absolutely perfect seal and allow the blade to close and open without the slightest friction. and with an incredible sweetness.

With regard to the blades then, I am experimenting with new types of hardening, which give hardnesses of 62-63 HRC and allow an exceptional edge hold and cutting quality for all types of use.

I make practically all the knives on an initial design of mine, they are all unique pieces made completely by hand down to the smallest details, one at a time, only in this way, in my opinion, a knife can be considered "artisanal".

Regarding the materials I use, I can say that for the blades I prefer RWL34 steel which is sintered from powders and guarantees the total absence of internal defects, sometimes I also use damascus, both stainless steel and carbon, for the uniqueness 'that give the knife, since each damask is always different from another.

For the handles, one of the most beautiful materials is the mammoth tooth, which can be found in a variety of wonderful colors, I also use fossil mammoth ivory, various briars, titanium and carbon fiber.

Most of the knives, however, are made entirely of steel, in order to then be engraved, always and strictly by hand, to transform the knife even more into a real work of art ...

Sergio Consoli - Folder Damascus Spirograph - Timascus and bronze Handle - N ° 454 - handcrafted knives

Details

Intended use: Collection

Type of production: Artisan by CIC Master Sergio Consoli

Production Lama: Italy

Blade: In spirograph damascus steel

Blade treatment: -

Handle: bronze bolsters, timascus with titanium spacers

Blade length: 95mm.

Blade thickness: 4mm.

Total length: 225mm.

Weight: 243g.

Closure: Liner Lock

Clip: titanium

Notes: Handmade by Master Sergio Consoli - knife number 454 made in 2018

Acknowledgments

Currently I make a limited number of knives a year and participate in some exhibitions, where among other things I have won my first prizes:

in 2005 at LAME SOTTO I PORTICI in Romano di Lombardia (BG) I was awarded as "best table on display"

always in the same year at the CULTER-EXPO in Novegro (MI) as "best folding knife"

I was also ranked second in the competition organized by the magazine LAME D'AUTORE as the best fixed hunting blade

then in 2007 at "Scarperia" I won the third prize for best folding

but above all again in 2007, to my great satisfaction, I reached the degree of MASTER OF THE ITALIAN KNIVING CORPORATION, a recognition received at the first exam.

Presentation of the craftsman

Creating a knife by hand is what I consider a real art form.

The satisfaction of seeing an object that comes from one's own hands, that takes shape and reaches mechanical, artistic and aesthetic perfection is what pays me back the most for all the hours of work and effort it takes to create a knife completely. by hand.

The passion for "cutting tools" has always been in me since I was a child and grew with me until the almost sudden decision to build my first knife myself, it was a "need", almost an inner necessity that I couldn't put off, my hands and my mind had to start creating, of course, what I had always been passionate about ... the knife!

I started at 40, in 2003, practically self-taught, I had no experience of manual work, but I had been a mechanical designer for many years and this allowed me to perfectly know the technique and all the various stages of mechanical processing.

Currently I am a member, with the rank of Master, which is the highest, of the Italian Knives Guild, an association recognized all over the world for the seriousness and above all quality of execution that all its members must maintain over time.

What I do now is what I consider my art form ..., to create "handcrafted, hunting and collectible knives".

They are knives made entirely by hand, only with an infinite series of files, a small drill for the holes and a sander for the concave grinding of the blades, nothing else!

I mainly make folding knives, which satisfy my desire to build perfect mechanical objects and perfection in the smallest details, even inside where they are not seen, is what distinguishes a knife created by hand, from one made industrially .

The mechanics then must be made in the best possible way, without counting the hours of work, only in this way the final result is guaranteed.

Of course, over the years I have refined my technique and currently I have improved the mechanics even more by inserting a system of ball bearings on the blade rotation, which guarantee an absolutely perfect seal and allow the blade to close and open without the slightest friction. and with an incredible sweetness.

With regard to the blades then, I am experimenting with new types of hardening, which give hardnesses of 62-63 HRC and allow an exceptional edge hold and cutting quality for all types of use.

I make practically all the knives on an initial design of mine, they are all unique pieces made completely by hand down to the smallest details, one at a time, only in this way, in my opinion, a knife can be considered "artisanal".

Regarding the materials I use, I can say that for the blades I prefer RWL34 steel which is sintered from powders and guarantees the total absence of internal defects, sometimes I also use damascus, both stainless steel and carbon, for the uniqueness 'that give the knife, since each damask is always different from another.

For the handles, one of the most beautiful materials is the mammoth tooth, which can be found in a variety of wonderful colors, I also use fossil mammoth ivory, various briars, titanium and carbon fiber.

Most of the knives, however, are made entirely of steel, in order to then be engraved, always and strictly by hand, to transform the knife even more into a real work of art ...

Specifications

| Brand | Sergio Consoli |

|---|---|

| Country of production | Italy |

| Blade Type | Folding |

| Blade Length | 9/10cm |

| Edge | Plain |

| Blade Tip | Drop point |

| Blade thickness | 4 mm |

| Blade Finish | None (Satin / Stonewashed) |

| Stainless Steel | Damascus |

| Handle Material | Metallic |

| colour | dark blue |

| Locking Type | Liner Lock |

| Designer | Sergio Consoli |

| Rarity | Unique |

| Materials and Finishes | 9 |

| Steel Quality | 8 |

| Strength | 7,5 |

| Practicality | 7,5 |

| Aesthetic | 8,5 |

| Quality/Price | 7,5 |